URM Universal Rubber MFG specialises in moulded rubber components. We develop and design rubber components in a multitude of polymers for many industries around the globe. We offer products in rubber, silicone, TPE and PU as well as Rubber to metal bonding.

URM Rubber-metal connections are most commonly used to filter vibrations and stop resonance. Metal such as brass, aluminum, steel or stainless steel can be offered with bonding to all elastomer types. URM Offers only the best quality of elastomers to ensure high endurance and parts lifetime.

These URM rubber fittings with clamps are made of high-quality EPDM rubber. The flexibility of the rubber fittings ensures a simple installation and service. The flexible rubber adaptors, often used as air intake hoses, have a smooth inside surfaces to minimize flow resistance.

URM produces all kind of rubber profiles. In function of the customers needs we choose the right manufacturing technique (steam vulcanization, salt bath vulcanization or hot air).

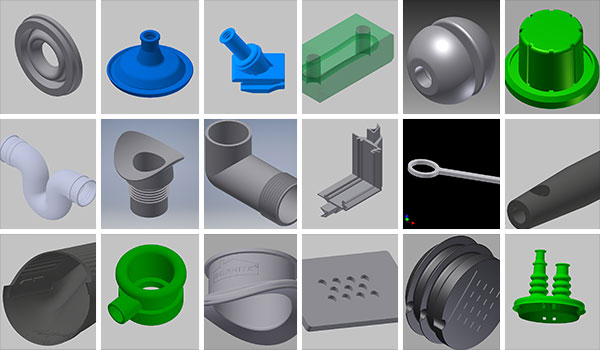

URM produces any kind of plastic moulded part via our injection moulding process. Designing plastic parts is a complex process which URM gladly provides at the best possible quality. With years of experience URM can recommend any type of form to ensure a sturdy and strong finished product.

URM produces rubber traffic cones in high quality rubber components. These flexible and durable cones are stackable and have a square base to prevent rolling when knocked over.

Designed and used to prevent the leakage and contamination of various fluids, including hydraulics, and chemicals, during the service, maintenance, and storage of machinery and equipment.

Silicone rubbers have the big advantage over other types of materials that they maintain their proper functioning at -60°C up to +250°C . Making them last much longer. They are available in all RAL colors and can be completely inertness (no taste or smell), making them extremely suitable in the food industry. We can produce simple extruded profiles but also custom made in complex cross-sections.

Silicone rubbers have exceptional weather and UV resistance. Thus, can be used outdoors for longer periods without any change in its physical properties. Silicone rubber has excellent moisture and steam resistance. It can be immersed in cold, warm or boiling water for longer periods. This rubber can be extruded into strips, tubes, solid cord or any custom profiles. We can deliver according the standards : for food applications to FDA or 1935/2004 – for the drinking water to KTW, DVGW or WRAS – for pharmacuetical industry to USP or ISO 10993

Silicone rubbers unique properties make them a key material choice for healthcare (resistance to bacteria) and food industry applications (FDA compliance) . There is no end to the number of silicone rubber applications in the field of electronics. A large number of household and kitchen accessories are equiped with silicone extruded materials. We can produce profiles with flame retardant properties as per standard UL-94 for closed spaces such as aircraft, subways and building interiors.