URM Universal Rubber MFG specialises in moulded rubber components. We develop and design rubber components in a multitude of polymers for many industries around the globe. We offer products in rubber, silicone, TPE and PU as well as Rubber to metal bonding.

URM Rubber-metal connections are most commonly used to filter vibrations and stop resonance. Metal such as brass, aluminum, steel or stainless steel can be offered with bonding to all elastomer types. URM Offers only the best quality of elastomers to ensure high endurance and parts lifetime.

These URM rubber fittings with clamps are made of high-quality EPDM rubber. The flexibility of the rubber fittings ensures a simple installation and service. The flexible rubber adaptors, often used as air intake hoses, have a smooth inside surfaces to minimize flow resistance.

URM produces all kind of rubber profiles. In function of the customers needs we choose the right manufacturing technique (steam vulcanization, salt bath vulcanization or hot air).

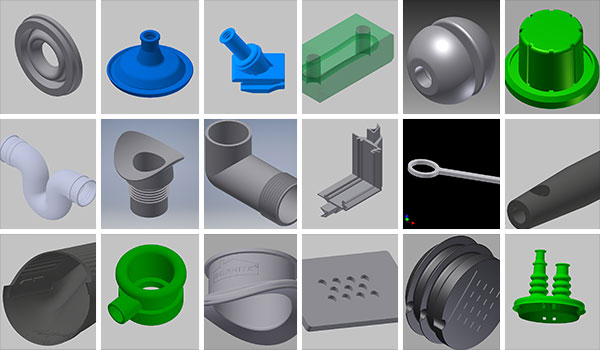

URM produces any kind of plastic moulded part via our injection moulding process. Designing plastic parts is a complex process which URM gladly provides at the best possible quality. With years of experience URM can recommend any type of form to ensure a sturdy and strong finished product.

URM produces rubber traffic cones in high quality rubber components. These flexible and durable cones are stackable and have a square base to prevent rolling when knocked over.

Designed and used to prevent the leakage and contamination of various fluids, including hydraulics, and chemicals, during the service, maintenance, and storage of machinery and equipment.

Our silicone Turbo charger hoses are ideal for connections between engine mounted charge air cooler system parts. They come in a range of straight, shaped or convoluted shapes, as required. The convoluted shapes are required when there are slight misalignments during fitment or functioning. The hoses are flexible enough to endure the vibrations caused due to these misalignments/ compressions/ 3-axial movements.

Turbo Hoses are with Metal fittings and Crimped ends also can be developed as per your requirement

. In URM house test rig available for life-cycle testing of the hoses (cyclic pressures between 0 and 3 bars, while maintaining temperatures of up to 220 degrees Celsius, inside and outside the hose.)

Turbo hoses are ideal for connctions between engine and mounted charge air cooler system parts